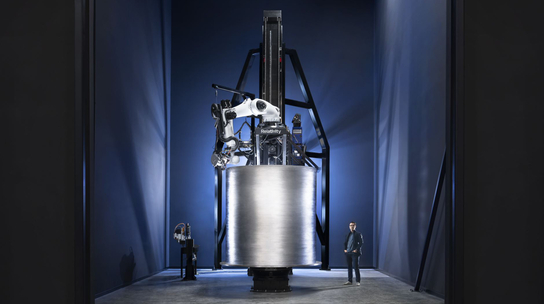

At Relativity Space, we have two audacious goals: to build the next great commercial launch company with Terran R and to become America's leading force in additive manufacturing innovation. Both contribute to our long-term vision of creating humanity’s industrial base on Mars, paving the way for interplanetary life to expand the possibilities of the human experience. This journey begins right here on Earth – where we design, build, and fly rockets to deliver customer payloads to orbit. Terran R, our medium-to-heavy lift reusable rocket, fulfills the growing demand for launch capacity, thanks to our iterative approach that accelerates design, testing, and development while minimizing costs. While our groundbreaking research and development in 3D printing pushes the boundaries of large-scale additive manufacturing.

Your journey with us is more than just a job – it’s an opportunity to shape the future of aerospace technology, additive manufacturing, and the human experience alongside a community of passionate, creative individuals. Join us on this extraordinary journey, as we work together to transform our vision into reality.

About the Team:

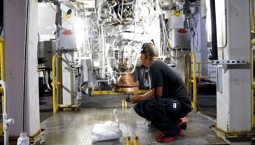

The Quality team supports all areas of production of Relativity’s hardware and defines the processes to do so. We work closely with engineering, manufacturing, supply chain, test and launch counterparts to ensure the quality of our products. We help lay the foundation for all processes within the product lifecycle – design, buy, build, test and launch. This is a unique opportunity to join a growing Quality organization and help lead the front on producing the industry’s highest quality 3D-printed parts and launch vehicle.

About the Role:

- Perform visual, dimensional, and functional inspections of flight hardware using variety of metrology tools (Micrometers, Bore gauges, thread gages, gage blocks, profilometers, comparators.)

- Provide detailed in-process and final inspections of production hardware using CAD model, drawings, process specifications, and/or work order requirements

- Provide detailed feedback to Machine Shop to help improve quality of the hardware

- Thoroughly review all hardware requirements and determine pass/fail status, documenting outcomes and any non-conformances or deviations found

- Provide detailed documentation that will be used to create nonconformance reports.

About You:

- A minimum of 3 years’ experience working as a Quality Inspector

- Excellent knowledge of GD&T, Ability to review drawings and identify improper callouts/datum structures, according to ASME Y14.5

- Demonstrate mastery with metrology hand inspection tools (calipers, micrometers, bore gages, thread gages, optical comparator, etc.)

- Proficient with common specs such as AS8879, NASM33537, MS51835, AS478, AS5202.

- Proficient at documenting inspection outcomes via detailed reports (AS9102, NCR’s, etc.)

- Experience with AS9100, ISO9001, or similar QMS

- Excellent communication and teamwork skills – ability to effectively communicate with engineering, shop floor techs and/or other inspection personnel

- Must be able to lift 25 lbs. unassisted and stand for extended period of time

- Must have an eye for detail to spot fod, defects, and burrs

Nice to haves but not required:

- Operation of CMM programs

- Knowledge of Aerospace hardware specifications, coating/processes, assemblies, etc.

- Experience at an Aerospace or automotive start-up

- Good computer skills including Microsoft Word, Excel, and Outlook

- Experience with NX, Teamcenter, Jira

- Experience with AS9100, ISO9001, or similar QMS

- Basic CNC skills

- Experience with any metrology software such as PC-Dmis, Verisurf, Polyworks, etc.

- Experience with CAM or CAD software such as Mastercam or Catia

At Relativity Space, we are committed to transparency and fairness in our compensation practices. Actual compensation will be determined based on experience, qualifications, and other job-related factors.

Compensation is only one part of our total rewards package. Relativity Space offers competitive salary and equity, a generous PTO and sick leave policy, parental leave, an annual learning and development stipend, and more! To see some of the benefits & perks we offer, please visit here.

Hiring Range:

$29—$38 USD

We are an equal opportunity employer and value diversity at our company. We do not discriminate on the basis of race, religion, color, national origin, gender, sexual orientation, age, marital status, veteran status, or disability status.

What We Do

A rocket company at the core, Relativity Space is on a mission to become the next great

commercial launch company. Terran R, our medium-to-heavy lift reusable launch vehicle, will

reliably deliver payloads to orbit on-time and on-budget for customers – meeting the needs of

growing demand for space infrastructure. Leveraging the benefits of additive manufacturing

to design, test, and iterate at a pace unmatched in the industry, we are changing the way

rockets are built and flown.

Our long-term goal is to create humanity’s industrial base on Mars, paving the way for

interplanetary life to fundamentally expand the possibilities of the human experience. The first

step toward this vision starts here on Earth, by building the next great commercial launch

company with Terran R

Why Work With Us

For 60 years, aerospace manufacturing has relied on fixed tooling and complex supply chains to

slowly build rockets comprised of hundreds of thousands of parts. Leveraging advances in

additive manufacturing, Relativity Space is strategically focused on reducing vehicle complexity,

cost, and time to market.

Gallery

Relativity Space Teams

Relativity Space Offices

Hybrid Workspace

Employees engage in a combination of remote and on-site work.

Given the dynamic nature and diversity of roles at Relativity Space, there is no one-size-fits-all approach for how every team works best.