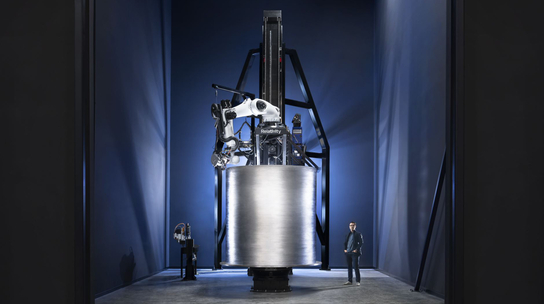

At Relativity Space, we have two audacious goals: to build the next great commercial launch company with Terran R and to become America's leading force in additive manufacturing innovation. Both contribute to our long-term vision of creating humanity’s industrial base on Mars, paving the way for interplanetary life to expand the possibilities of the human experience. This journey begins right here on Earth – where we design, build, and fly rockets to deliver customer payloads to orbit. Terran R, our medium-to-heavy lift reusable rocket, fulfills the growing demand for launch capacity, thanks to our iterative approach that accelerates design, testing, and development while minimizing costs. While our groundbreaking research and development in 3D printing pushes the boundaries of large-scale additive manufacturing.

Your journey with us is more than just a job – it’s an opportunity to shape the future of aerospace technology, additive manufacturing, and the human experience alongside a community of passionate, creative individuals. Join us on this extraordinary journey, as we work together to transform our vision into reality.

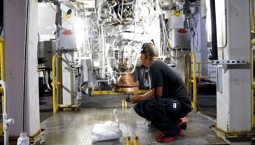

The engine manufacturing department's mission is to produce high performing products & manufacturing systems by continuously innovating on cost, quality, and lead time. Through cross-functional collaboration, high levels of accountability, and a focus on safety we support the Terran R program. We are responsible for providing design feedback on new hardware iterations, developing new manufacturing methods and systems, and ultimately building engine and vehicle hardware for testing prior to our first launch. Our team's highlights from the last 6 months include the MDC of the first Aeon-R engine, completing thousands of hours of PBF printing, building and testing over 50 valves of 26 different iterations, and implementing large scale process improvements along the way.

- Lead a team of dedicated manufacturing engineers through hardware development and production for Aeon-R turbopump assemblies

- Drive progress from early development to qualification and into high-rate production

- Identify talent and grow the team through training and mentorship specific to turbopump hardware and lean manufacturing principles

- Establish and continuously develop the production line, processes, and tools for building and testing turbopump assemblies

- Assist with developing the business tools and processes that will be used to manufacture the early development articles and into production

- Work closely with cross-functional partners to continuously improve manufacturing productivity and reliability

- Develop and own production metrics across product lifecycle and drive improvements both tactically and strategically

- Bachelor of Science degree in aerospace, mechanical, manufacturing engineering, or equivalent

- 3+ years of experience building and testing hardware in a manufacturing environment

- Experience authoring work instructions and/or test procedures to build and verify complex assemblies

- Experience interfacing with design engineering, manufacturing, and production personnel to produce complex assemblies

- 1+ years of experience in leading others

- Experience in leading, executing, and managing projects in a fast-paced environment

- Experience applying knowledge of tooling development as a manufacturing representative

- Experience working under a fast-paced startup

- 1+ years of leadership experience leading other leaders

- Extensive experience with turbomachinery design, manufacturing, or test

- Experience with rotor balancing

- Experience in scaling from development to production environment

- Experience building strong relationships with technicians and production environment

The below-range represents Relativity Space’s current good-faith pay scale for this role. Relativity Space reserves the right to modify or update this range at any time.

Compensation is only one part of our entire total rewards package. To see some of the benefits & perks we offer, please visit here: https://px.sequoia.com/relativityspace

Hiring Range:

$138,000—$169,000 USD

What We Do

A rocket company at the core, Relativity Space is on a mission to become the next great

commercial launch company. Terran R, our medium-to-heavy lift reusable launch vehicle, will

reliably deliver payloads to orbit on-time and on-budget for customers – meeting the needs of

growing demand for space infrastructure. Leveraging the benefits of additive manufacturing

to design, test, and iterate at a pace unmatched in the industry, we are changing the way

rockets are built and flown.

Our long-term goal is to create humanity’s industrial base on Mars, paving the way for

interplanetary life to fundamentally expand the possibilities of the human experience. The first

step toward this vision starts here on Earth, by building the next great commercial launch

company with Terran R

Why Work With Us

For 60 years, aerospace manufacturing has relied on fixed tooling and complex supply chains to

slowly build rockets comprised of hundreds of thousands of parts. Leveraging advances in

additive manufacturing, Relativity Space is strategically focused on reducing vehicle complexity,

cost, and time to market.

Gallery

Relativity Space Teams

Relativity Space Offices

Hybrid Workspace

Employees engage in a combination of remote and on-site work.

Given the dynamic nature and diversity of roles at Relativity Space, there is no one-size-fits-all approach for how every team works best.